Found 2 results

Article

14 March 2025A Conceptual Design of Industrial Asset Maintenance System by Autonomous Agents Enhanced with ChatGPT

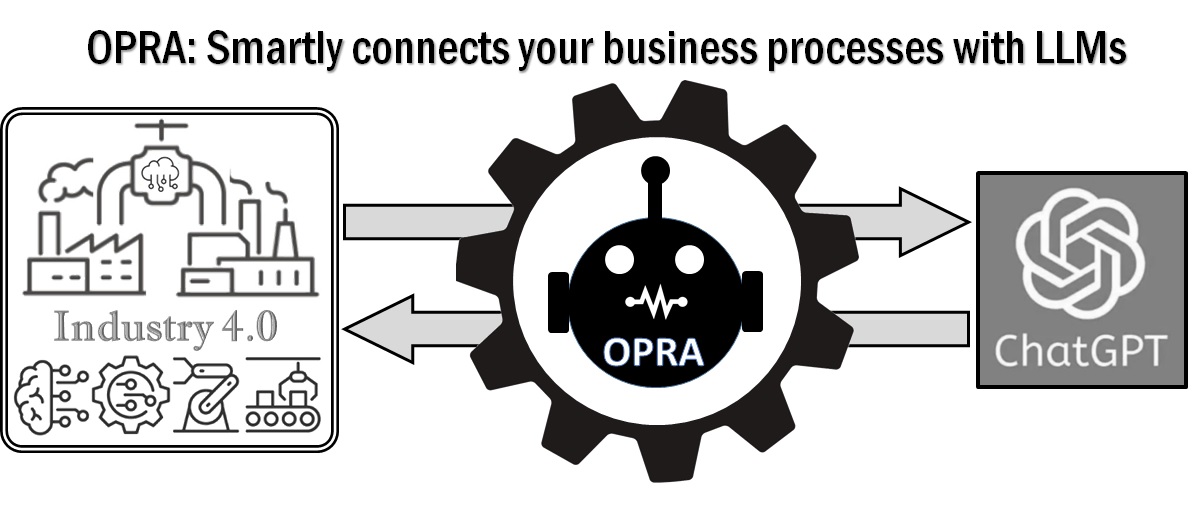

This article introduces OPRA (Observation-Prompt-Response-Action) and its multi-agent extension, COPRA (Collaborative OPRA), as frameworks offering alternatives to traditional agent architectures in intelligent manufacturing systems. Designed for adaptive decision-making in dynamic environments, OPRA enables agents to request external knowledge—such as insights from large language models—to bridge gaps in understanding and guide optimal actions in real-time. When predefined rules or operational guidelines are absent, especially in contexts marked by uncertainty, complexity, or novelty, the OPRA framework empowers agents to query external knowledge systems (e.g., ChatGPT), supporting decisions that traditional algorithms or static rules cannot adequately address. COPRA extends this approach to multi-agent scenarios, where agents collaboratively share insights from prompt-driven responses to achieve coordinated, efficient actions. These frameworks offer enhanced flexibility and responsiveness, which are critical for complex, partially observable manufacturing tasks. By integrating real-time knowledge, they reduce the need for extensive training data and improve operational resilience, making them a promising approach to sustainable manufacturing. Our study highlights the added value OPRA provides over traditional agent architectures, particularly in its ability to adapt on-the-fly through knowledge-driven prompts and reduce complexity by relying on external expertise. Motivational scenarios are discussed to demonstrate OPRA’s potential in critical areas such as predictive maintenance.

Article

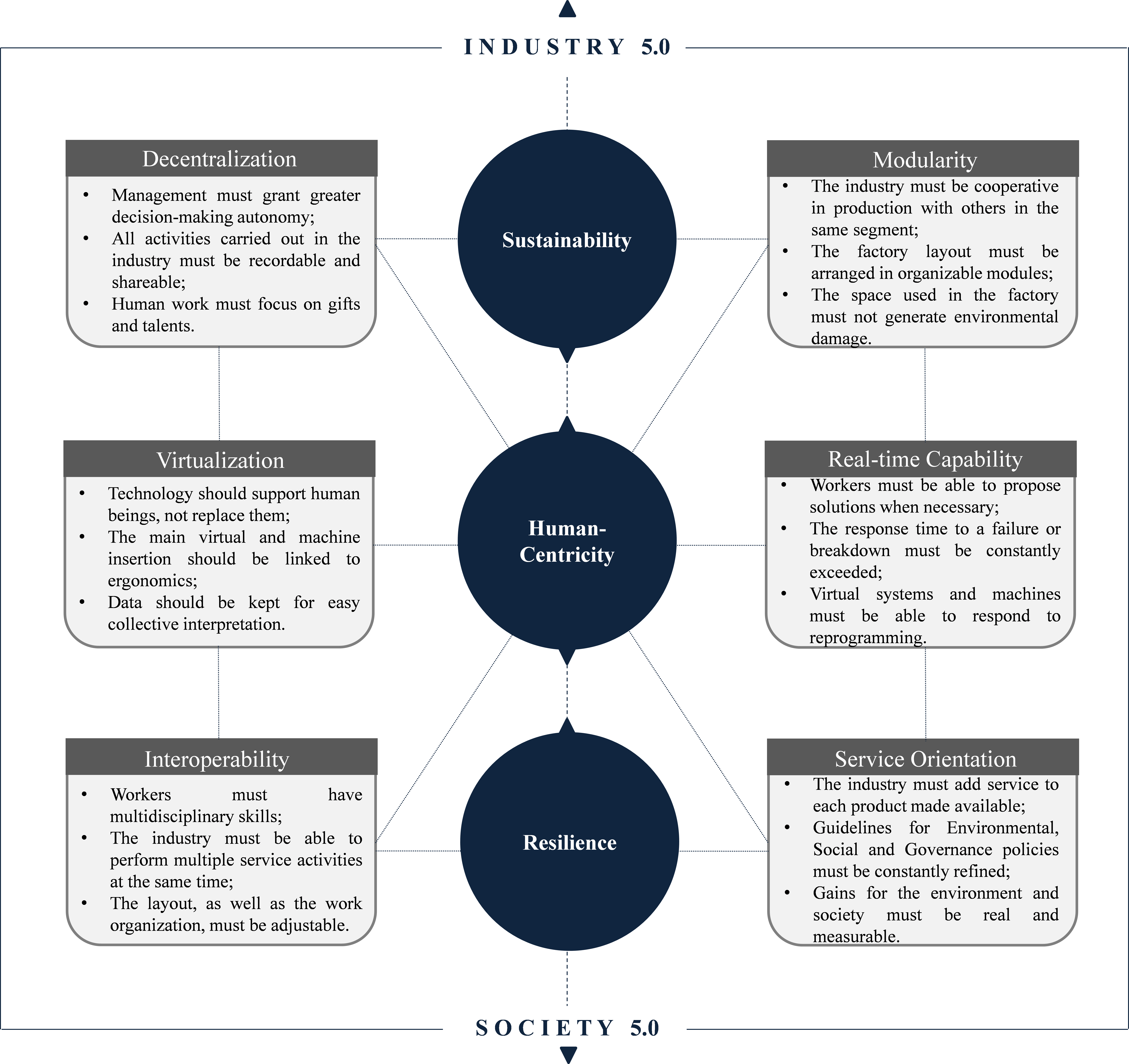

20 November 2024Contextualization of Industry 4.0 Design Principles for the Imminent Industry 5.0 Scenario

The Fourth Industrial Revolution, known as Industry 4.0 (I4.0), has introduced a completely disruptive pace compared to the rhythm of the three previous industrial revolutions. With a wide range of technologies, design principles, and a high potential to replace the human workforce, this industry presents aspects that urgently require greater attention. With a purpose close to meeting this need, Industry 5.0 (I5.0) emerges, a milestone not yet registered with historical facts but with great hopes for positive changes. While I4.0 maintains design principles for its complete activity, I5.0 has a supporting tripod for its operation. As I5.0 is still perceived as an evolutionary character of I4.0, it is expected that for the time being, it will use these same design principles for its activity and may later include new principles. Based on this context, this article seeks to contextualize, in a descriptive way, the functioning of design principles 4.0 for the imminent industrial context 5.0. The article uses a conceptual approach based on previously published literature on the subject of design principles in I4.0. Although the characteristics of I5.0 are not yet fully known, it is assumed that it has a more refined character than I4.0, so that points that presented a positive, significant, and already consolidated result are maintained for the new model. The distinctive feature of this article is its presentation of a textual analysis that breaks down the potential contributions of design principles in relation to the three core values of Industry 5.0: Sustainability, Human-Centricity, and Resilience.