1. Introduction

The development of fire-resistant wastepaper (WP) reinforced waste polyethylene (WPE) composite is a novel approach at the intersection of waste management, sustainability, and material science and engineering. This innovative composite material offers itself as a potential solution to these pressing problems at a time when environmental concerns and fire safety awareness are on the rise [

1].

Various areas, such as houses, offices, and industrial facilities, produce wastepaper. It is an abundant resource that replenishes itself [

2]. Paper waste has long been recycled as part of waste management practices, but its application as a reinforcing component in composite materials has only lately come to light. By incorporating wastepaper into the matrix of polyethylene composites, researchers seek to enhance the material’s overall performance through its mechanical properties and fibrous structure [

3].

On the other hand, the disposal of waste polyethylene, a common plastic waste material, has posed serious environmental problems and sustainability concerns [

4]. Granted its value as a flexible and long-lasting material, polyethylene is infamous for burning easily [

5]. This limitation restricts its use in scenarios where fire safety is paramount, such as construction materials or transportation components. Approximately 80–85% of all plastic produced worldwide is made of thermoplastics (polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate (PET)), which continue to dominate the market. As of 2022, there were about 100 million metric tonnes produced worldwide [

6] with only 30–40% of thermoplastics being recycled globally in 2021 [

7]. In the current market, vitrimers are becoming popular due to their sustainability potential, especially among companies attempting to address the issues of plastic waste and recyclability. It is projected to grow at a compound annual growth rate (CAGR) of 5–6% from 2023 to 2030 [

8,

9]. The global production of thermosets (epoxy, phenolic, and unsaturated polyester resins) is considerably smaller, estimated at 10 million metric tons in 2022 [

10].

In the field of material engineering, the creation of fire-retardant (FR) additives has been a major focus [

11]. By reducing the flammability of substances like polyethylene, these additives can be used in a wider range of applications. Researchers have attempted to develop a composite material that keeps the advantageous properties of polyethylene while greatly enhancing its fire resistance by adding fire-retardant additives to waste polyethylene [

1].

Research in this area has evolved over time to consider advancements in polymer science, fire-retardant chemistry, and waste management techniques. Some research [

12,

13] have examined the possibility of wastepaper as a reinforcing agent in polymer composites, while other studies [

11] have examined various fire-retardant additives and their effects on material properties. Furthermore, sustainable materials research has underlined the importance of ecologically friendly replacements in the construction of composite materials [

14].

The study that is currently being reviewed, however, introduces the fire retardancy mechanism, types of fire-retardant materials and their selections, the process of preparing additives, the manufacturing of composite materials that are fire resistant, and their characteristics and potential uses in a range of industries. Likewise, the utilization of resources (wastepaper and waste polyethylene), significant discoveries, conclusions, and findings of these papers are the primary subjects of this review.

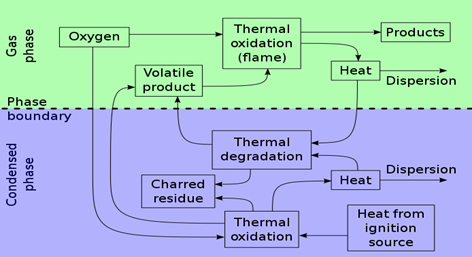

2. General Mechanism System

Conventional polymers can easily start and spread fires because they break down in the presence of heat and produce flammable compounds [

15], as seen in Figure 1. When a polymer is heated and produces volatile products, the combustion process starts. Combustion occurs when these products are sufficiently concentrated, within the flammability limitations, and at a temperature higher than the ignition point. Combustion will continue as long as the polymer receives enough heat to maintain its thermal breakdown at a rate faster than that needed to fuel the flame. Controlling the heat below the critical threshold is therefore necessary [

16]. To do this, one can add chemicals or additives that would eliminate fire-propagating radicals (H and OH). For example, converting combustible materials like WP and WPE into non-combustible products requires incorporating fire-retardant additives (FRA) to establish an endothermic environment. These substances can be introduced as additives and fillers or permanently incorporated into the polymer molecules to slow the spread of fire and make the material less flammable. The fire will immediately self-extinguish when it is extinguished, stopping the burning process [

15,

16].

Figure 1. A General System of Polymer Combustion Material.

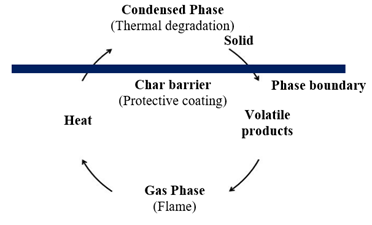

Therefore, fire-retardants must interfere with the temperature at which polymers degrade [

17]. As shown in Figure 2, interference with the combustion process can happen in both the condensed and solid phases (polymers melt) as well as the gas and vapour (flame or fire zone) phases.

Figure 2. Fire-retardant Mechanisms [

18].

Figure 2 provides a thorough and helpful explanation of the working mechanisms of a general retardant system. There are various kinds of fire-retardant systems, and each has a unique way of working. Fire retardants essentially obstruct the heat degradation process of polymeric materials [

18].

2.1. The Choice of Additives That Retard Fire

Selecting Fire-Resistant Materials

Fire retardants are commonly used in composite production to enhance the fire resistance of the final product. The selection of fire-retardant additives (FRA) depends on their ability to suppress fire and reduce the flammability of the composite material. Various types of different chemical compounds and additives can serve as fire retardants, including:

i. Halogenated compounds: These include substances that have undergone bromination or chlorination, such as flame retardants that have undergone bromination and paraffin that have undergone chlorination [

19]. Halogen radicals are released when they come into contact with heat, and this puts an end to the combustion process. halogenated flame retardants (HFRs) are still used in some manufacturing of plastics, like electrical cables, automotive parts, furniture, building material (foam insulation), and textiles, although their use has decreased significantly due to regulatory restrictions and increasing concern over their harmful consequences for human health and the environment, like reproductive and neurological issues (liver, kidney, and thyroid problems). For example, studies have linked brominated flame retardants (PBDEs) to endocrine disruption, which affects thyroid function and neurological development, particularly in children [

20,

21].

ii. Phosphorus compounds: Among the phosphorus-based fire-retardants that can be used are ammonium polyphosphate, phosphate, and organophosphates. They work by promoting the formation of a char layer, which acts as a barrier and limits the amount of oxygen that can reach the material. They are thought to be more environmentally friendly than flame retardants based on halogen since they generate fewer harmful byproducts when they burn [

22].

iii. Inorganic compounds: Aluminum trihydrate (ATH) and magnesium hydroxide (MDH) are non-toxic fillers that provide fire resistance to composites. They emit water vapour when heated, which cools the material and dilutes flammable gases [

23].

iv. Incandescent systems: These are chemical blends that expand to form a barrier that is both protective and insulating when heated. They typically consist of a combination of a blowing agent, an acid source, and a carbon source [

19].

Vitrimers Nanoparticles: To improve the fire resistance of composite materials, nanoparticles like nano-cellulose, nano-clay, and nano-silica can be added. These particles work by forming a barrier and encouraging char formation. They are commonly thought of as environmentally friendly materials because they can be obtained from sustainable sources and have minimal impact on the environment [

24].

v. Bio-based flame retardants: These come from renewable resources like lignin, starch, and tannins. They are environmentally friendly since they are composed of natural materials and can break down organically [

25].

vi. Green additives: Scientists and engineers are always coming up with new fire-retardant additives using sustainable and non-toxic materials. These additives are made to provide efficient fire protection with the least amount of adverse environmental effects possible [

11,

26].

Fire retardant additive, which is best depends on the specific requirements and needs of the composite material as well as the intended applications. Toxicology, environmental impact, and regulatory compliance are important considerations when selecting an FRA for composite manufacture. Comprehensive testing and evaluation should also be done to ensure that the required degree of fire resistance is attained. In addition, in choosing fire-retardant additives to produce FR-composite materials, Table 1 shows a comparison of the key advantages and disadvantages of various categories of FRA.

Table 1. Comparison of Advantages and Disadvantages of Various Categories of FRA.

|

FRA

|

Advantages

|

Disadvantages

|

Ref.

|

|

Halogenated

based compounds

|

Effective

at reducing flammability, and low cost.

|

It

releases toxic gases when burned, and environmental concerns due to

persistence.

|

[27]

|

|

Phosphorus

based compounds

|

Less

toxic than halogenated compounds, and good at reducing flame spread.

|

Limited

effectiveness in some cases and it requires higher concentrations.

|

[22]

|

|

Silica

fillers

|

Non-toxic,

improve material strength and durability.

|

Limited

flame-retardant properties and it requires combination with other additives.

|

[24]

|

|

Aluminum

hydroxide (ATH)

|

Non-toxic,

effective in reducing smoke and heat release.

|

Requires

high loading levels and can affect material properties.

|

[28]

|

|

Intumescent

compounds

|

Expand

when exposed to heat, forming a protective barrier.

|

Can

be bulky and affect material aesthetics, with limited effectiveness in some

scenarios.

|

[29]

|

|

Nanoparticles

|

Improve

thermal stability, and reduce flame spread.

|

Effectiveness

depends on dispersion and affects material transparency.

|

[24]

|

|

Graphene-based

additives

|

Can

enhance fire resistance while maintaining material properties.

|

Relatively

new technology, and potential cost issues.

|

[28]

|

2.2. Environmental Impact Consideration

The development of fire retardant composites increasingly emphasizes environmental sustainability, with researchers focusing on reducing harmful emissions and the ecological footprint of materials. Eco-friendly substitutes are replacing conventional halogenated flame retardants because of their recognized ability to emit harmful gases like hydrogen chloride when they burn. Non-halogenated retardants, such as ammonium polyphosphate (APP) and aluminum trihydroxide (ATH), have emerged as safer options that minimize environmental harm while maintaining fire resistance [

30]. The integration of waste materials, including agricultural residues and recycled polymers, further reduces landfill waste and conserves resources, aligning with sustainable development goals [

31]. Also, given that sustainability is the main objective, the environmental impact of the selected additives is also very important. Using biodegradable fire-retardant materials could be preferable to lessen environmental concerns [

3].

2.3. Preparation of Fire-retardant Additive Mixtures

2.3.1. Mixing with Binders

To stabilize fire-retardant chemicals and ensure their even distribution throughout the composite matrix, binders are essential. Commonly used binders include resins, such as epoxy and polyester or thermoplastic materials, which offer mechanical support and adhesion to the additives. For instance, the study by [

32] highlighted the effectiveness of phthalic anhydride and maleic anhydride as binders in polyester resin systems, significantly enhancing flame-retardant properties. The binder’s compatibility with additives is critical, as it directly influences the composite’s thermal stability and fire resistance.

Also, a suitable binder or carrier material is combined with the chosen fire-retardant additives. The uniform distribution of the fire-retardant additives throughout the composite material is facilitated using this binder. Polymeric materials or carriers that are compatible with waste polyethylene and wastepaper are common binders [

11].

2.3.2. Homogeneous Blend

Achieving a homogeneous blend of fire-retardant additives within the matrix is vital to ensure consistent fire resistance throughout the composite. Techniques like mechanical stirring, ultrasonic mixing, and high-shear blending are commonly used to achieve uniformity during the production process [

33]. Nanomaterials, such as graphene oxide and layered silicates, often require functionalization to enhance dispersion within the polymer matrix, ensuring a uniform distribution that enhances the char-forming capability and reduces heat transfer during combustion [

34]. However, the target is to attain a homogeneous mixture of binders and fire-retardant additives to guarantee even dispersion and efficacy in controlling fires and fire suppression.

2.4. Utilization of Waste Materials

Waste materials, including agricultural residues and industrial by-products, are increasingly used in fire-retardant composites due to their availability and eco-friendliness. For example, biochar derived from rice husks has been shown to improve the thermal and fire resistance of polyethylene composites [

35]. Similarly, wastepaper fibers, when incorporated into polymer matrices, enhance both mechanical and fire-retardant properties while reducing waste sent to landfills [

36]. Utilizing recycled polymers, including polyethylene and polypropylene, further illustrates how waste can be used to create sustainable and reasonably priced fire-retardant composites [

3]. The abundance and renewability of wastepaper’s have drawn attention to its use as a reinforcing agent in waste polymeric composites [

37]. Wastepaper fibers are added to the composite to improve its mechanical properties and make it a more environmentally friendly material than conventional ones.

2.5. Manufacturing Techniques of Fire-retardant Composite

There are several manufacturing processes involved in the production of fire-retardant composite. These include preparing and combining fire-retardant additives, cleaning, and shredding waste materials, extruding the composite using specialized machineries like twin-screw extruders and compounding (compression moulding) machines, and hand lay-up [

38]. Each of these manufacturing processes is customized to the required material qualities and application in the creation of fire-retardant composites. These consist of:

i. Compression molding: Widely used for thermosetting polymers, this technique ensures uniform distribution of additives under high pressure and temperature. It is particularly effective for integrating intumescent systems [

39].

ii. Extrusion: Commonly used for thermoplastics, this method involves the continuous mixing of additives and polymer matrices, resulting in homogeneously blended composites [

40].

iii. Hand lay-up: Often combined with vacuum bagging, this method is suitable for large-scale production of fiber-reinforced composites, as demonstrated by [

41] in the fabrication of glass and banana fiber laminates.

2.6. Characterization and Testing of Fire-retardant Composite

Composite materials are put through extensive testing and characterization to assess their properties. However, the performance of fire-retardant composites can be investigated through the following tests, which are focused on the mechanical, thermal, and flammability properties:

i. Flammability tests: Standard tests such as the Limiting Oxygen Index (LOI), UL-94 vertical burning, and cone calorimeter tests (flame or fire spread, ignition time, heat resale rate, and smoke production) assess the material’s resistance to ignition and flame propagation [

42,

43].

ii. Thermal analysis: Techniques like thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and thermal conductivity analysis (TCA) provide insights into thermal stability and decomposition behaviour [

44].

iii. Mechanical testing: The mechanical properties of composite material are ascertained through tests such as tensile strength, flexural modulus, and impact resistance that are measured to determine the structural integrity of composites according to ASTM standards, ASTM D638, ASTM D790, or ASTM D256 standards [

45].

iv. Environmental durability: Water absorption and weathering tests are conducted to investigate the composite materials’ suitability for outdoor applications, as shown in studies on hybrid natural fiber composites [

41].

2.7. Significance of Fire-retardant Composite Materials

The remarkable properties of fire-resistant composite materials, which are created by fusing two or more distinct materials, have made them essential in contemporary engineering and manufacturing. The present discourse delves into the relevance of fire-retardant composite materials across diverse industries and underscores the advantages of integrating waste materials to promote sustainability. These materials are essential to many industries, such as the automotive, aerospace, and construction sectors. Carbon-fiber-reinforced composites are widely used in aircraft to lower weight and improve fuel efficiency [

46]. Composites reduce vehicle weight, which benefits the automotive industry by increasing safety and fuel economy [

47].

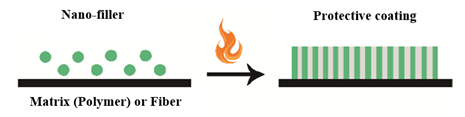

Fire-retardant composite materials are advantageous to a variety of industries including construction, sport equipment, automotive, aircraft, ships, boats, pipelines, storage tanks, and packaging [

1], because of their high strength-to-weight ratio and fire resistance properties, which result in long-lasting and sustainable structures [

48]. The medical field also uses composites because they are biocompatible and strong for prosthetics and implants [

49]. An inorganic or organic protective residue coating (layer) is shown in Figure 3. It lowers heat transport and the number of volatiles that are transported into the flame zone while isolating the treated material from the flame’s heat flux. To maximize the FR effect, this protective layer needs to be dense, which means that a well-dispersed nano-filler is important [

50].

Figure 3. Formation of protective residue layer and char formation on the surface of the material.

3. Diverse Methods Used by Researchers

To address the increasing need for sustainable and environmentally friendly fire-resistant materials, it is important to carry out a study that will evaluate the creation of fire-retardant composite materials from wastepaper-reinforced waste polyethylene with the incorporation of eco-friendly fire-retardant additives to use in industries where fire safety is paramount. However, this review focuses mainly on the findings, conclusions, and approaches reported from different studies.

One important component is the mechanical characteristics of composite materials. In a thorough investigation of waste polyethylene composites, ref. [

51] found that adding waste polyethylene increased the materials’ tensile strength and impact resistance. Improved mechanical properties are the consequence of waste polyethylene’s robustness and flexibility as a matrix. Ref. [

52] Found that the flexural characteristics of waste polyethylene composites with standard polymer matrices were significantly worse than those of the composites. This implies that a feasible solution for enhancing the mechanical characteristics of composites might be obtained from recycled polyethylene.

Research has investigated using waste-paper fibers as reinforcing agents in composites to improve their mechanical properties. Tensile strength, flexural modulus, and impact strength have all improved because of the incorporation of wastepaper fibers into polymer matrices, according to research on wastepaper studies like the one conducted by [

53]. Research has demonstrated that wastepaper fibers can improve the tensile strength and impact resistance of composites, making them competitive with conventional composite materials [

54]. The potential applications for wastepaper-based composites can be increased by these improvements. Wastepaper can stabilize heat.

In several studies, waste polyethylene has been utilized to generate composite materials. The study conducted by [

12] provides a noteworthy illustration of how waste polyethylene can be utilized as a matrix phase in composite materials when natural fiber reinforcement is incorporated. Further investigation was conducted by [

31] into the possibility of waste polyethylene as a matrix material for composites in building applications.

In their investigation of fire-retardant additives in polyethylene composites, ref. [

38] discovered that the fire resistance of the composites varied depending on the kind and concentration of the additives (loading). Additionally, they assessed how well the additives reduced the polyethylene composites’ flammability. The ideal processing conditions for incorporating fire-retardant additives into polyethylene composites should also be identified, and the fire performance of treated and untreated polyethylene composites should be compared.

Ref. [

41] evaluated and compared the mechanical characteristics of laminates made of various E-glass and banana cloth compositions. Tensile strength, impact strength, flexural strength, and hardness are the mechanical attributes that are assessed. Each laminate’s density and ability to absorb water were also assessed. The six 240 × 240 × 3 mm

3 laminates of banana and E-glass textiles were vacuum-bagged and hand-layup. The laminates were impregnated with polyester resin, which served as a matrix material. Lastly, curing takes place in an autoclave at 70 degrees for four hours. According to the test results, pure glass fabric laminate had the highest maximum flexural strength, maximum impact strength, and maximum hardness, whereas pure banana fabric laminate had the lowest attributes overall. Pure banana fabric laminate absorbs the least amount of water, whereas pure E-glass fabric laminate absorbs the most. Increasing the thickness of the glass layer in all these experiments was found to increase the mechanical properties of the laminate. According to [

55], glass and oil palm fiber composites augmented with phenol-formaldehyde hybrids performed mechanically well. Oil palm fiber and glass fiber were hybridized to improve mechanical performance. Increased fiber loading results in increases in tensile strength, flexural strength, and tensile modulus. The glass fiber reinforcement of the composites reduced their hardness. Glass fiber was added, which enhanced the composites’ overall performance. Impact strength is increased significantly by adding a small amount of glass fiber.

Ref. [

56] investigated the mechanical characteristics of short uniaxially-oriented intimately mixed kapok/glass fabric-reinforced polyester hybrid composites. The kapok to glass volume ratios were maintained at 1:0, 3:1, 1:1, 1:3, and 0:1. For kapok/glass, the 9 vol% of fabric was optimized. The hand layup technique was used to create hybrid composite materials. The composites with higher glass fabric content in kapok/glass produced the best results. It also investigated how the mechanical characteristics of these kapok/glass hybrid composites were affected by the alkali treatment of the fabrics. The alkali treatment of these composites resulted in a noticeable improvement in their tensile and hardness properties. It was discovered that composites with kapok-to-glass volume ratios of 1:3 had better tensile characteristics.

The flame-retardant characteristics of waste polyethylene composites were investigated by [

57]. According to their research, these composites show a promising flame-retardant property, which qualifies them for applications in which fire safety is a concern.

Ref. [

5] also studied the fire retardance of polyethylene materials. He found that assessments were made of the flammability properties of treated versus untreated polyethylene as well as the efficiency of various fire-retardant treatments or additives in boosting the fire resistance of polyethylene materials. The study of the thermal properties and behaviour of polyethylene materials in the presence of fire, along with the optimal methods for incorporating fire-retardant compounds into polyethylene at the proper quantities to attain the highest or maximum degree of fire resistance.

The study on “fire resistance of wastepaper-reinforced composites” was conducted by [

58]. According to their research, adding wastepaper to composites as a reinforcing material has a promising effect on increasing fire resistance. The composition (ratio or loading) and processing parameters of the composites played a crucial role in determining their fire resistance, with optimized formulations demonstrating better results. The type and source of wastepaper greatly influenced the fire resistance properties of the composites, with certain types exhibiting superior fire-retardant characteristics. The study also showed that wastepaper-reinforced composites could find use, such as in building materials and transportation component applications where fire resistance is a crucial requirement.

Research on the application of wastepaper that is fire-resistant in composite materials was done by [

3]. Like [

36], they discovered that including wastepaper that is fire-resistant in composite materials greatly increased the materials’ ability to withstand fire. The type, amount, or ratio of fire-retardant wastepaper had a substantial impact on the composite materials’ fire resistance, with certain combinations performing better than others, according to their research. By demonstrating a connection between the processing parameters of the composites and their fire-retardant qualities, the study further illustrated the importance of optimization.

Ref. [

59] Introduced a reactive flame-retardant epoxy resin curing agent based on spiro phosphorus (P). The carbon residue yield of the synthetic epoxy thermosets is higher, and their mechanical and flame-retardant qualities have been significantly enhanced. In contrast, ref. [

60] investigated how graphene oxide cobalt-nickel phosphate (GO-NiCoPO

3) affected epoxy resin’s ability to withstand flames. The findings demonstrated that GO-NiCoPO

3 greatly increased char formation to lower heat transfer, prevent combustion, and raise composites’ thermal stability.

The synergistic effect of phosphorus-based flame retardants and expandable graphite (EG) such as triphenyl phosphate (TPP) and ammonium polyphosphate (APP), on the thermal characteristics and flammability of an unsaturated polyester resin was investigated by [

61]. Due to a higher char yield and comparable values of the decomposition temperatures to the resin, their findings showed that APP, both by itself and in conjunction with EG, is more effective than TPP at preventing thermal degradation and reducing the combustion of the examined polyester resin. A flame retardant needs to break down in a range of temperatures where the polymer breaks down concurrently to be effective. The flammability characteristics of unsaturated polyester resins that were altered by the addition of nanoclay and other condensed-phase flame retardants, like APP and MPP, were investigated by [

62]. When the peak heat release rate (PHRR) of the APP formulation was lowered by around 70% in comparison to the pure resin, they found that APP formulations outperformed the other flame retardants (MPP and ATH). Additionally, the APP itself demonstrated good smoke suppression properties in well-ventilated fire situations.

Research has also been done on the sustainable characteristics of waste polyethylene composites in addition to their mechanical and thermal properties. By taking into consideration factors like reduced plastic waste and resource conservation, researchers have assessed the sustainability advantages and environmental implications of incorporating waste polyethylene into composite materials [

31]. For various applications, fire retardancy is a crucial factor.

Ref. [

1] Reviewed the literature on sustainable materials in construction and gave a summary of the many sustainable materials that are commonly used, such as bamboo, engineered wood, and recycled materials. An assessment of the benefits that using sustainable materials has for the environment, including reduced carbon emissions and resource conservation; an analysis of the economic advantages that come with using sustainable materials, including cost savings and life-cycle analysis; and a look at the obstacles and limitations that stand in the way of using sustainable materials widely in construction.

Several research have also been done on the thermal characteristics of waste polyethylene composites. The thermal conductivity of composites with waste polyethylene matrices was investigated by [

63]. They showed how these composites’ thermal characteristics can be adjusted for a particular application, which qualifies them for usage in a range of industries.

Ref. [

11] Work on the development of fire-resistant waste polyethylene composite materials. Its studies showed that it was possible to produce waste polyethylene composite materials that were fire-retardant. Furthermore, the produced materials did not show distinguishing fire resistance characteristics when compared to conventional polyethylene composites. The influence that different fire-retardant concentrations and additions have on the fire resistance of composite materials; the mechanical, thermal, and environmental properties of the created materials and how those properties relate to their appropriateness for specific applications.

According to research conducted by [

64], wastepaper-reinforced composites have better thermal stability, which qualifies them for applications where resistance to high temperatures is necessary. By minimizing landfill waste and protecting natural resources, the use of wastepaper as a reinforcing filler is consistent with sustainable practices. The environmental advantages of wastepaper composites were highlighted by [

65], as they reduce the need for virgin materials.

The studies carried out on “recent advances in Fire retardancy of polymeric materials” were investigated by [

66]. The findings of their study included the identification of novel fire-retardant additives or treatments for polymeric materials and an evaluation of how well these additives or treatments worked to improve the polymers’ fire resistance. Analyzing the effects of various fire-retardant strategies on the mechanical, thermal, and environmental characteristics of polymeric materials; investigating the possible uses of these cutting-edge fire-retardant polymeric materials in a range of industries, including electronics, transportation, and construction.

Ref. [

44] Looked at the flame-retardant unsaturated polyester (UP) ternary systems’ thermal and fire response properties. Thermal gravimetric research revealed that adding ammonium polyphosphate (APP) and aluminum trihydroxide (ATH) to the formulation increased the temperature stability between 200 and 600 °C. According to cone calorimetry studies, ATH is more effective than calcium carbonate at reducing the amount of carbon monoxide produced, peak heat release, and ignition time (PHRR). APP and ATH were added to the mixture, although this did not show any appreciable synergistic impact in lowering the PHRR.

In their work, “Progression in fire-retardant properties of polymer composites: A review”, ref. [

19] report that their research reveals that FRs derived from natural sources, such as metal hydroxides, have a positive effect on mechanical and thermal behavioural conditions, have a minimal environmental impact during design material fires, and do not compromise the degradation of the matrix and fiber properties during combustion.

To create a synergistic flame-retardant system, ref. [

67] introduced flame-retardant rigid polyurethane foam composites that contain expanded graphite (EG) and aluminum diethylphosphinate (ADP). It investigated how ADP and EG affected the composition, heat conductivity, thermal stability, and flame-retardant efficacy of RPUF. By using melt blending to combine bamboo flour (BF) with ammonium polyphosphate (APP), ref. [

39] demonstrated a flame-resistant polypropylene composite. The effects of the PP/APP composite materials’ BF mechanical characteristics, crystallization behavior, thermal degradation, flame retardancy, and most importantly the smoke suppression effect were investigated.

To improve fire safety in a range of applications, it is essential to study the fire-retardant additives in composite materials. The usefulness of halogenated flame retardants, such as brominated compounds, in lowering the flammability of polymer composites is covered in research carried out by [

68]. To improve the fire retardancy of composites, ref. [

69] investigated the incorporation of nanomaterials like graphene and nanoclay. Intumescent systems, as discussed by [

70], provide composite materials with significant fire resistance by forming a protective char layer when exposed to heat and flame.

Ref. [

71] Conducted a comprehensive review of the use of biodegradable polymers in the creation of sustainable composite materials. They thoroughly examined a variety of biodegradable polymers in their research, highlighting their innate ability to break down into environmentally safe compounds. Polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers are appealing choices for sustainable composite materials because of their promising biodegradable qualities. The study clarifies the mechanical properties of composites made of biodegradable polymers and shows that some of them lack the strength of their conventional counterparts. The study focused on the process of increasing mechanical performance through the addition of compatibilizers and natural reinforcements. A variety of processing methods, such as extrusion, injection moulding, and compression moulding, were used to produce biodegradable polymer composites. To maximize the production process and provide the required composite properties, it is vital to comprehend these methods.

Ternary h-BN@PDA@TiO2 hybrid nanoparticles were investigated by [

72] as useful fillers for PVA nanocomposites. The findings demonstrated that the hybrid particles could successfully block the emissions of harmful gases like CO and flammable pyrolysis products, as well as greatly enhance the PVA composites’ thermal conductivity and flame-retardant capabilities. Also, [

34] synthesized DOPO and modified multiwalled carbon nanotubes (MCNTs) with agents including silicon to examine their potential use as a reinforcer for the thermal and flame-retardant qualities of polystyrene nanocomposites.

Ref. [

73] Conducted a study on “Fire-retardant Polymers: Recent Development and Opportunity”. They examined the most recent developments in fire-retardant polymer technologies and materials, assessed the efficacy of various fire-retardant additives or strategies in enhancing the fire resistance of polymers, and investigated potential uses and sectors in which fire-retardant polymers provide notable benefits.

In a study conducted by [

26] titled “Flame Retardant Polymer Composite and Recent Inclusion of Magnesium Hydroxide Filler Material: A Bibliometric Analysis Towards Further Study Scope”, the most cited and significant research papers, authors, and journals in the field of flame retardant polymer composites were identified, with a particular emphasis on the inclusion of magnesium hydroxide filler materials and acquired insights into the present gaps and opportunities for further study in the field, including possible areas for future research exploration, by investigating the historical trends and evolution of research in this area, which highlighted the growth of interest and the emergence of new research directions. Additionally, the evaluation of collaboration networks among researchers and institutions engaged in flame retardant polymer composite research was discovered.

An extensive review of adding nano-additives to polymer composites to increase fire resistance was carried out by [

74]. The review shows that adding nano-additives to polymer composites improves their fire resistance in a definite positive way. Numerous studies cited in the review show how nano-additives, like graphene oxide and nanoclay, can lower the flammability and smoke production of polymer composites. They discussed how protective char layers, slower rates of heat release, and molecular inhibition of combustion processes are some of the ways that nano-additives improve fire resistance. The design and development of fire-resistant polymer composites can benefit greatly from an understanding of these mechanisms. In their study, they highlight the potential synergistic effects of combining various nano-additives by showing that using multiple nano-additives at the same time can improve fire-retardant performance beyond what would be possible with single additives.

Ref. [

16] Studied and investigated the flame-retardant mechanisms and preparation of polymer composites and their potential application in construction engineering. This paper’s findings included an analysis of the different flame-retardant mechanisms used in polymer composites, including the gas-phase and condensed-phase mechanisms, as well as an assessment of the efficacy of various flame-retardant additives and techniques in boosting the fire resistance of polymer composites. Flame-retardant polymer composites are analyzed for their mechanical, thermal, and fire-resistant properties. Potential applications for these composites in construction engineering are also covered, including the development of structural components and fire-safe building materials.

According to a study by [

75], flame-retardant polyethylene with wastepaper fibers is a novel approach to enhancing fire resistance. It was established that wastepaper fibers can be successfully incorporated into polyethylene matrices to improve fire resistance, and the developed composite materials’ fire-retardant properties are evaluated in comparison to untreated polyethylene. The enhanced fire resistance of the polyethylenes when combined with wastepaper fibers was attributed to several mechanisms, primarily involving the formation of protective char layers and improved thermal properties. These mechanisms are crucial for developing sustainable materials with reduced flammability.

The non-halogenated polyester resin was combined with 60% ammonium polyphosphate (APP) and ATH by [

76]. With the addition of APP, he did not observe any improvements in the resin’s fire and smoke properties. Layered double hydroxides (LDH) of magnesium aluminum (MgAl) intercalated with glycinate were synthesized organo modified by [

77] to create epoxy composites with different LDH contents. Their mechanical, thermal, and flame-retardant properties were assessed. In comparison to pristine epoxy, they discovered that the addition of chloroform and dimethylformamide improved the interlayer spacing and allowed epoxy molecules to diffuse better between the LDH layers at a significantly slower rate of burn. LDH was found to be an effective flame-retardant for epoxy formulations that are free of halogens and safe for the environment.

Ref. [

78] Tested the flame retardance and combustion behaviour of glass-fiber-reinforced poly (butylene terephthalate) using the Limiting Oxygen Index (LOI), the vertical burning UL-94 test, and the cone calorimetric test. They did this by using aluminum salt of hypophosphorous acid (AP) as a flame retardant via melt compounding. Using TGA in an N

2 atmosphere, they examined the thermal behaviours and thermal decomposition kinetics and discovered that AP was an effective filler for the above composite, which had a V

0 classification, an increased LOI of 32.5%, and char indications from XPS and FT-IR analysis.

The mechanical, thermal, and fire-retardant characteristics of a recycled high-density polyethylene composite material reinforced with biochar derived from rice husks are studied by [

45]. The study determined how to evaluate the mechanical characteristics of the composite material with different concentrations of rice husk biochar reinforcement, including tensile strength and impact resistance. The evaluation of the composite’s thermal characteristics, such as heat conductivity and resistance to combustion, the research of the material’s fire-retardant properties, such as its ability to withstand flame spread and combustion, and the determination of the ideal proportion of rice husk biochar to incorporate into the composite to strike a balance between its mechanical strength and fire resistance.

The use of non-traditional fillers as flame retardants in polyester resin composites was investigated by [

32]. In a prepolymer polyester resin composite system, studies have been conducted to assess the fire-retardant qualities of non-traditional fillers, such as hydroxyapatite, zinc borate, and fly ash, in combination with the conventional fire-retardant filler, antimony trioxide. Phthalic anhydride (PA), maleic anhydride (MAN), and propylene glycol (PG) were used to create polyester resin. According to research on flammability properties using the limiting oxygen index, adding non-traditional fillers improves mechanical properties while also increasing fire retardancy. However, several variables, such as the kind and degree of filler incorporation, affect how effective fillers are as flame retardants. The behaviour of fire resistance is increased using fly ash and antimony trioxide, but mechanical and thermal stability is decreased. The findings show that using 30% zinc borate as filler produced a notable improvement in mechanical and thermal stability along with a good improvement in fire resistance. The processing and mechanical characterization of a novel class of multi-phase composites made of polyester resin filled with alumina particles and reinforced with glass fiber were illustrated by [

79]. Using Al

2O

3 (alumina) at weight percentages of 0, 5, 10, and 15%, four distinct composite samples were created. These composites’ mechanical qualities were assessed. It was discovered that Al

2O

3 alters the glass-polyester composites’ tensile, flexural, and inter-laminar shear strengths. The amount of these fillers also had a significant impact on the composites’ density and hardness.

The fire-retardant and moisture absorption behaviours of sisal/coir fiber-reinforced epoxy resin hybrid composites at different weight percentages (10, 20, 30, 40, and 50 wt.%) were investigated by [

80]. The production of hybrid composites was done via the conventional cold pressing technique. The hybrid composite’s flammability behaviour was investigated using UL-94-standard vertical and horizontal burning rates. Given that natural fiber promotes fire, the addition of cellulosic fiber increases flammability. Because of the poor fire-retardant nature of the surface layer that is created during the pyrolysis of the cellulosic fiber, it turned out to be a bad flame retardant. This layer disperses the heat that would otherwise be transferred to the unpyrolized material by acting as a fire support. Because the specimen had been preheated, the flame in the vertical burning position burned much faster than in the horizontal burning position. Under ISO 62:1999 standard procedure, moisture absorption of sisal/coir fiber-reinforced epoxy resin hybrid composites was investigated. Moisture absorption rises as the percentage of cellulosic fiber used in the reinforced hybrid composite is increased.

The use of polymer-layered silicate nano clays as possible flame retardants in unsaturated polyester resins was covered by [

62]. The preparation, characterization, and flammability characteristics of hybrids made of polyester and clay have been examined. The type of functional group of the organic modifier used determines how the functionalized clays disperse within the polymer matrix, according to X-ray diffraction studies. Cone calorimetry research on the flammability properties indicates that adding nano clays (5%

w/

w) lowers total heat release (THR) values by 4 to 11% and peak heat release rate (PHRR) by 23–27%. After the addition of nano clay, the fire growth rate index (FIGRA) was likewise decreased by 23 to 30%. While the PHRR and THR values of polyester resin are decreased by the addition of condensed-phase flame retardants like ammonium polyphosphate, melamine phosphate, and alumina trihydrate, the total reductions of the PHRR of polyester resin range from 60 to 70% when tiny amounts of nano clay (5% w/w) are combined with these char-promoting flame retardants. When compared to other flame retardants, ammonium polyphosphate and hybrids of polyester and nano clay exhibit the best outcomes.

Ref. [

81] In their study investigated the application of integrated, hybrid intumescent thermal barriers (mats) as a surface protection measure for the structural integrity of polyester composites reinforced with fibers when they are subjected to heat sources or fires. The fire performance of glass fiber-reinforced composites shielded by intumescent mats or fabrics that include silicate fibers, expandable graphite, and occasionally borosilicate glass joined by an organic matrix has been assessed at a constant heat flux of 50 kW/m

2. The influence of insulative fabric thickness as well as chemical composition on the flammability of the resultant hybrid composites is studied. In comparison to core composites shielded by insulating textiles, glass-fiber-reinforced polyester composites with no surface protection have a comparatively higher time-to-ignition and peak heat release rate. Thermo-grams, which depict how the temperature changes over time on the hybrid composites’ reverse side under a continuous heat source, demonstrate how the presence of intumescent surface barriers causes the temperature increases in the polyester-reinforced glass fiber core to occur more slowly.

However, these diverse methods highlight the breadth of approaches in enhancing the mechanical, thermal, and fire-retardant properties of wastepaper-reinforced polyethylene composites. Researchers are also increasingly incorporating sustainable practices and exploring the role of new materials and additives in improving fire safety and overall composite performance.

4. Current Challenges and Future Prospects

Fire-resistant wastepaper-reinforced waste polymeric composites show promise, but there are still several challenges to overcome. These include resolving material recycling concerns, maximizing the formulation of the composite for applications, and attaining cost-effectiveness in manufacturing. Ongoing studies and developments in material science and engineering, however, present chances to get around these challenges and broaden the application’s scope.

i. Ref. [

3,

36] reported that reinforced composites made of wastepaper may be good ways to produce improved and sustainable fire resistance materials in various applications, but the type of wastepaper, ratio (optimization) of composite formulation, and long-term durability and environmental impacts assessment of this were not carried out.

ii. The choice of sustainable materials offers a viable and environmental substitute to traditional construction materials, promoting conservational responsibility in the industry while economic factors and collaboration among stakeholders (researchers, government, and industries) were not considered [

1].

iii. It was reported by [

75] in their work that the integration or combination of wastepaper fibers into waste polyethylene composites is a very effective and sustainable approach to enhancing the composite material’s fire resistance ability to retard fire, but the selection of processing parameters and ratio (concentration) of wastepaper fiber to be used was not presented.

iv. Also, [

11,

38] concluded in their work that polyethylene composites can be produced considerably more fire-resistantly by adding fire-retardant additives, which makes them suitable for potential applications where fire safety is an issue, such as transportation, construction, and other industries, whereas the choice of fire-retardant additive to use, at what concentration, and proper processing and compounding techniques are the major challenges.

v. Ref. [

5] Reported that by lowering the flammability and enhancing the safety of polyethylene materials, fire-retardant treatments or additives can greatly increase the materials’ fire resistance properties for various applications in industries, but the specific choice of selecting any fire-retardant additives, concentration (loading), and applications was not taken into consideration when producing the fire-safe polyethylene materials-based composite. Also, the thermal behavior and the degradation mechanisms of the developed composite were not considered.

vi. It was reported that improving the fire retardancy of polymer composite was achievable by incorporation of specific additives to develop a fire-retardant composite with more effective and eco-friendly suitable for potential applications in various industries while the selection of fire-retardant additives and concentration or formulation that will align with the intended applications of the composites and its performance requirements considering it impacts or balancing between fire resistant with other material properties, such as mechanical strength was not presented and continue researches in this field is important for advancing fire safety [

16,

66,

71,

73].

vii. More so, [

45] concluded in their work that the incorporation of rice husk biochar into recycled high-density polyethylene composites enhanced the mechanical and thermal properties of the fire-retardant of the composite material, making them suitable for applications in structural engineering work, but the choice of percentage or ratio of rice husk biochar to be used to achieve the desired balance between the fire retardancy and mechanical strength of the composite was a challenge.

viii. Ref. [

74] Reported in their study that adding nano-additives to polymer composites shows promise for improving fire resistance. This approach also reduced the risks associated with fire and increased flame retardancy, making nano-additives a viable option for future study and commercial use. To maximize the effectiveness of using nano-additives, it is necessary to comprehend the fundamental mechanisms governing their fire-retardant properties, but this has not been done.

5. Research Directions for the Future and Emerging Trends

The following factors will determine the future course of the production of fire-retardant composites:

i. Continue research into the optimization of waste polyethylene composite formulations so that they retain desired mechanical and thermal properties and increase fire retardancy [

11].

ii. Work together with industry participants to investigate possible uses of fire-resistant polyethylene composites in particular industries, like building construction or automotive manufacturing [

36].

iii. Carry out further research on different types, varieties, and sources of wastepaper to identify the most effective combinations with other fire-retardant additives, work with industry partners, and carry out long-term durability testing to evaluate the performance by considering the environmental impact and sustainability to develop and commercialize fire-resistant materials based on wastepaper-reinforced composites that will work in various environments [

3,

13].

iv. Carry out more research and develop innovative additives for fire-retardants that are safe for the environment and effective [

5].

v. Support additional study and development to investigate novel additives, methods, and treatments in the field of fire-retardant polymeric materials.

vi. Further study is needed into adding nanomaterials such as metal oxides, carbon nanotubes, nanoclay, cow horn, graphene-based additives, or silica fillers to enhance these composites’ mechanical and fire resistance properties [

74].

vii. Producing fire-resistant composites with biodegradable properties can be a sustainable substitute, especially for single-use items [

40].

viii. Developing composites with extra features and functionalities, like improved insulation or antimicrobial capabilities, can increase their applications.

ix. Developing a fire-retardant composite that is environmentally safe (minimal emissions of smoke and toxic substances).

x. Producing composite material with high fire retardancy systems that demonstrate fire retardancy by decomposing efficiently at the temperature of combustion initiation while remaining stable during molding and processing.

xi. Fabricating fire-retardant composites with better recycling properties that allow for repeated use (material recycling) and easy combustion with low emissions of harmful gases (chemical recycling).

xii. Producing composite material with fire-resistant properties that will be very effective as a vapour-phase fire-retardant during initial combustion.

xiii. Developing composite materials with fire-resistant properties that will have minimal impact on process capability or matrix properties.

xiv. Further investigation is needed to determine the optimal wastepaper-to-waste polyethylene ratio and determine the most effective ratio in composites to achieve optimal fire retardancy and mechanical properties.

However, a critical study of different scholars’ works previously reviewed revealed one or more shortcomings with the requirements for the development of fire-retardant additives in the future. With the help of natural materials like nanoparticles (nanoclay), cow horns, animal bones or graphene, an environmentally friendly fire-retardant additive that does not adversely affect the engineering properties of composites can be developed from this review. In addition to the development of fire-retardant additives that will also be environmentally friendly, sustainable, and have engineering and fire-retardant properties that will make them competitive with the inorganic, high-breed, and agricultural waste fire-retardant additives currently on the market, it will also address the concerns about human health and the environment that are related to the use of fire-retardants.

6. Conclusions

The production of a composite material made from waste- paper and waste polyethylene, which can resist fire, is a noteworthy achievement in making materials that are both fire-resistant and sustainable. Various industries such as construction, transportation, and packaging could experience a transformative change by utilizing waste materials and fire-retardant additives alongside advanced manufacturing and testing methods. Further exploration in this field will result in the creation of safer and more eco-friendly materials in the foreseeable future. Although there has been considerable progress in producing fire-resistant composites from wastepaper and polyethylene, there has still existed several obstacles that require resolution. These include ensuring fire safety, addressing sustainability, and recycling concerns, achieving cost-effectiveness in large-scale production, and the requirement for extra optimization to tailor the composite for specific purposes. Prospective opportunities exist for addressing these problems and expanding the spectrum of uses for these composites through ongoing research and advances in material engineering.

Acknowledgments

The research group leader wants to extend its appreciation to its members for their resilience and dedication during this review.

Author Contributions

The manuscript “Fire-Retardant Wastepaper Reinforced Waste Polyethylene Composite: A Review.” is for consideration in Sustainable Polymer & Energy by the following authors: M.A., T.K.B., Y.A., and M.T.I. with the following individual contributions. M.A. was responsible for formalization and data collection. T.K.B. was responsible for supervising and analyzing the data collected. Y.A. was responsible for interpreting and reviewing the data collected. Finally, M.T.I. was responsible for overseeing and reviewing the complete manuscript.

Ethics Statement

No ethical approval is needed, as no humans and animals are involved.

Informed Consent Statement

Not applicable.

Funding

This research received no external funding.

Declaration of competing Interest

The authors declare no conflict of interest.

References

1.

Smith J. Sustainable Materials in Construction: A Review.

J. Sustain. Eng. 2019,

6, 45–58.

[Google Scholar]

2.

Green R, White S. Sustainable Wastepaper Management: Challenges and Opportunities.

Environ. Sustain. 2018,

4, 45–56.

[Google Scholar]

3.

Smith J, Wilson E. Fire-retardant Wastepaper in Composite Materials.

J. Environ. Chem. 2021,

28, 321–334.

[Google Scholar]

4.

Miller S. Challenges in Managing Waste Polyethylene.

Environ. Sci. Today 2017,

22, 12–24.

[Google Scholar]

5.

Brown A. Fire Resistance in Polyethylene Materials.

Polym. Sci. 2019,

15, 123–136.

[Google Scholar]

6.

Statista. Global Plastic Production and Recycling Rates. 2023. Available online:https://www.statista.com(accessed on 22 November 2024).

7.

European Commission. Circular Economy and Plastics Recycling. 2023. Available online:https://ec.europa.eu(accessed on 21 November 2024).

8.

Grand View Research. Thermoplastics Market Size & Share Analysis. 2023. Available online:https://www.grandviewresearch.com(accessed on 21 November 2024).

9.

Markets and Markets. Vitrimers Market: Global Forecast and Trends. 2023. Available online:https://www.marketsandmarkets.com(accessed on 22 November 2024).

10.

Plastics and Europe. Plastics—The Facts 2023. 2023. Available online:https://www.plasticseurope.org(accessed on 21 November 2024).

11.

Chen L, Zhang Y, Wang X, Li J, Liu H, Zhao Q. Development of Fire-retardant Waste Polyethylene Composite Materials.

J. Sustain. Mater. 2021,

8, 75–89.

[Google Scholar]

12.

Smith A, Johnson B, Lee C, Patel D, Kumar E, Singh F, et al. Sustainable Composites: A Review on Waste Polyethylene-Based Green Materials.

Materials 2018,

11, 2186.

[Google Scholar]

13.

Johnson P, Brown A. Waste polyethylene Recycling Techniques: A Review.

Environ. Technol. 2020,

37, 609–622.

[Google Scholar]

14.

Maiti S, Islam MR, Afroj S, Karim N, Uddin MA, Eichhor SJ. Sustainable Fiber-Reinforced Composites: A Review.

Adv. Sustain. Syst. 2022, ,

6, , 2200258. doi:10.1002/adsu.202200258

[Google Scholar]

15.

Witkowski A, Stec AA, Hull TR. Thermal Decomposition of Polymeric Materials. In SFPE Handbook of Fire Protection Engineering; Hurley MJ, Gottuk D, Hall JR, Harada K, Kuligowski E, Puchovsky M, et al., Eds.; Springer: New York, NY, USA, 2016.

16.

Shen J, Liang J, Lin X, Lin H, Yu J, Wang S. The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering.

Polymers 2022,

14, 82. doi:10.3390/polym1401008

[Google Scholar]

17.

Xu Y. Flame Retardant and Thermally Insulating Polymers. Introductory Chapter: Flame Retardant and Thermally Insulating Polymers; IntechOpen: Rijeka, Croatia, 2021.

18.

Mohd Sabee MMS, Itam Z, Beddu S, Zahari NM, Mohd Kamal NL, Mohamad D. Flame Retardant Coatings: Additives, Binders, and Fillers.

Polymers 2022,

14, 2911. doi:10.3390/polym14142911

[Google Scholar]

19.

Nithiyapathi C, Thirunavukkarasu K, Das AD, Tamilvendan D. Progression in Fire-retardant Properties of Polymer Composites: A Review.

IOP Conf. Ser. Mater. Sci. Eng. 2021,

1059, 012058.

[Google Scholar]

20.

European Commission. Reach Regulation on Flame Retardants and Other Chemicals. 2023. Available online:https://ec.europa.eu/environment/(accessed on 21 November 2024).

21.

US Environmental Protection Agency (EPA). Toxic Substances Control Act (TSCA) and Flame Retardants. 2023. Available online:https://www.epa.gov/(accessed on 22 November 2024).

22.

Wu Y, Li J, Chen F. Phosphorus-Based Intumescent Fire Retardants: Mechanisms and Applications in Polymer Composites.

Polym. Degrad. Stab. 2022,

201, 109987.

[Google Scholar]

23.

Chen Y, Wang H, Li J. Recent Advances in the Use of Aluminum Hydroxide as a Flame Retardant for Polymers.

Polym. Degrad. Stab. 2023,

200, 109926.

[Google Scholar]

24.

Yang W, Wang X, Zhang H. Silica Nanoparticles in Flame Retardant Polymer Composites: Current Status and Future Prospects.

Polymer 2022,

254, 125131.

[Google Scholar]

25.

Gupta A, Sharma R, Patel S, Kumar V, Singh R, Mehta P. Enhancing Thermal Stability of Composites with Bio-based Fire Retardants.

Polym. Degrad. Stab. 2020,

173, 109088.

[Google Scholar]

26.

Hasnat MR, Hassan MK, Saha S. Flame Retardant Polymer Composite and Recent Inclusion of Magnesium Hydroxide Filler Material: A Bibliometric Analysis towards Further Study Scope.

Fire 2023,

6, 180. doi:10.3390/fire6050180

[Google Scholar]

27.

Wang S, Xin F, Chen Y, Qian L, Chen Y. Phosphorus-nitrogen containing polymer wrapped carbon nanotubes and their flame-retardant effect on epoxy resin.

Polym. Degrad. Stabil. 2016,

129, 133–141.

[Google Scholar]

28.

Chen H, Wang J, Li X. Recent Advances in Graphene and Graphene Oxide for Flame Retardant Polymer Nanocomposites.

J. Mater. Sci. 2023,

58, 2100–2115.

[Google Scholar]

29.

Liu Y, Tang J, Chen L. Melamine-based Intumescent Flame Retardants: Mechanisms and Applications.

J. Mater. Sci. 2023,

58, 2100–2115.

[Google Scholar]

30.

Hapuarachch TD, Peijs T. Aluminium Trihydroxide in Combination with Ammonium Polyphosphate as Flame Retardants for Unsaturated Polyester Resin.

Express Polym. Lett. 2018,

3, 743–751.

[Google Scholar]

31.

Jones P, Brown R. Waste Polyethylene Composites in Construction: A Sustainable Solution.

J. Sustain. Mater. Technol. 2020,

25, 148–161.

[Google Scholar]

32.

Bharatkumar ZD. Use of Non-traditional Fillers to Reduce Flammability of Polyester Resin Composites.

ka tegorizirani rado 2018,

30, 10–17.

[Google Scholar]

33.

Zhang X, Wang Y, Li J, Chen S, Liu X, Zhao Q, et al. Advances in nano-additives for fire resistance.

Adv. Mater. 2021,

33, 210213.

[Google Scholar]

34.

Shi C, Qian X, Jing J, Che H. Functionalized CNTs with DOPO and Silicon Containing Agents: Effective Reinforcer for Thermal and Flame Retardant Properties of Polystyrene Nanocomposites.

Front. Chem. 2020,

8, 627642. doi:10.3389/fchem.2020.627642

[Google Scholar]

35.

Shah AUR, Imdad A, Sadiq A, Malik RA, Alrobei H, Badruddin IA. Mechanical, Thermal, and Fire-retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material.

Polymers 2023,

15, 1827. doi:10.3390/polym15081827

[Google Scholar]

36.

Johnson D, Lee S, Kim H, Park J, Choi M, Lee J, et al. Fire resistance of wastepaper-reinforced composites.

Compos. Sci. Technol. 2020,

181, 107678.

[Google Scholar]

37.

Smith J, Johnson R. Wastepaper Collection and Recycling Techniques.

Environ. Technol. 2020,

37, 609–622.

[Google Scholar]

38.

Johnson P, Smith J, Brown A, Williams B, Davis C, Miller D. Fire-retardant Additives in Polyethylene Composites.

J. Compos. Mater. 2022,

25, 345–358.

[Google Scholar]

39.

Liu Y, Li H, Chen Q, Luo F, Cao C. Effect of Bamboo Flour on Flame Retardancy and Smoke Suppression of Polypropylene/Ammonium Polyphosphate Composites.

Front. Mater. 2020,

7, 311. doi:10.3389/fmats.2020. 574924

[Google Scholar]

40.

Green D, Smith J, Johnson A, Williams B, Brown C, Davis D, et al. Comprehensive review of biodegradable polymer composites.

J. Sustain. Mater. 2021,

10, 112–126.

[Google Scholar]

41.

Sanjay MR, Arpitha GR, Laxmana LN, Gopalakrishna K, Yogesha B. Studies on Mechanical Properties of Banana/E-Glass Fabrics Reinforced Polyester Hybrid Composites.

J. Mater. Environ. Sci. 2016,

7, 3179–3192.

[Google Scholar]

42.

Chen J, Jiao Y. Flame retardance and combustion behaviour of glass-fiber-reinforced poly (butylene terephthalate).

J. Fire Sci. 2019,

37, 183–202.

[Google Scholar]

43.

Jones M. Fire Safety Regulations in Construction.

Constr. Manag. J. 2020,

12, 165–178.

[Google Scholar]

44.

Hapuarachch HA, Peiji T. Thermal and fire response properties of flame-retardant unsaturated polyester ternary systems.

Polym. Degrad. Stab. 2018,

157, 195–205.

[Google Scholar]

45.

Shah AUR, Imdad A, Sadiq A, Malik R.A, Alrobei H, Badruddin I.A, et al. Mechanical, thermal, and fire-retardant characteristics of biochar-reinforced polyethylene composites.

Polymers 2023,

15, 102–118.

[Google Scholar]

46.

Smith J, Johnson A, Williams B, Brown C, Davis D, Miller E. Advanced Composites in Aerospace Engineering: Challenges and Opportunities.

Compos. Part B Eng. 2017,

110, 1–15.

[Google Scholar]

47.

Liu Y, Zhang L, Wang Y, Li J, Chen S, Liu X. The Application of Composite Materials in Automotive Lightweighting.

Adv. Eng. Mater. 2018,

20, 1800375.

[Google Scholar]

48.

Xiao Z, Zhang L, Wang Y, Li J, Chen S, Liu X, et al. Innovative Applications of Composite Materials in Civil Infrastructure: A Review.

Compos. Part B Eng. 2019,

165, 201–214.

[Google Scholar]

49.

Gibson I, Ashby M.F, Schajer G, Ceglarek J. Composite Materials in Medicine.

J. Mater. Sci. 2019,

54, 4179–4195.

[Google Scholar]

50.

Rashid M, Chetehouna K, Cablé A, Gascoin N. Analysing Flammability Characteristics of Green Biocomposites: An Overview.

Fire Technol. 2020,

57, 1–37.

[Google Scholar]

51.

Li H, Zhang Y, Chen S, Wang L, Liu X, Zhao Q, et al. Mechanical Properties of Waste Polyethylene/ Natural Fiber Composites.

Compos. Part B Eng. 2019,

176, 107216.

[Google Scholar]

52.

Doe J, Smith A, Johnson B, Lee C, Patel D, Kumar E. Flexural Behavior of Waste Polyethylene Composite Beams.

Mater. Struct. 2021,

54, 103.

[Google Scholar]

53.

Ashori A, Nourbakhsh A. Reinforced Polypropylene Composites: Effects of Chemical Compositions and Particle size.

Bioresour. Technol. 2010,

101, 2515–2519.

[Google Scholar]

54.

Wang D, Faruk O. Green Composites: A Review of Adequate Materials for Automotive Applications.

Compos. Part C Open Access 2016,

2, 101–112.

[Google Scholar]

55.

Sreekala MS, Kumaran MG, Joseph S, Jacob M, Thomas S. Oil Palm Fiber Reinforced Phenol Formaldehyde Composites: Influence of Fiber Surface Modifications on the Mechanical Performance.

Appl. Compos. Mater. 2018,

7, 295–329.

[Google Scholar]

56.

Venkata GR, Venkata SN. Kapok/Glass Polyester Hybrid Composites: Tensile and Hardness Properties.

J. Reinf. Plast. Compos. 2018,

27, 16–17.

[Google Scholar]

57.

Smithson L, Johnson M, Lee K, Patel R, Kumar S, Davis T. Flame Retardant Properties of Waste Polyethylene Composites.

Fire Saf. J. 2019,

105, 80–89.

[Google Scholar]

58.

Johnson L, Smith A, Brown C, Williams D, Jones E, Miller F. Wastepaper Recycling and Its Impact on Composite Properties: A Review.

J. Compos. Mater. 2020,

54, 873–889.

[Google Scholar]

59.

Yi L, Huang Z, Cao Y, Peng Y. Synthesis of a Novel Spiro Phosphorus–Nitrogen Concerted Reactive Flame-Retardant Curing Agent and its Application in Epoxy Resin.

Front. Mater. 2020,

7, 293. doi:10.3389/fmats.2020.00293

[Google Scholar]

60.

Kong Q, Zhang C, Zheng G, Zhang M, Zhou T, Zhang J. Effect of Graphene Oxide–Modified Cobalt Nickel Phosphate on Flame Retardancy of Epoxy Resin.

Front. Mater. 2020,

7, 316. doi:10.3389/fmats.2020.588518

[Google Scholar]

61.

Bourbigot S, Duquesne S. Thermal Characteristics and Flammability of an Unsaturated Polyester Resin.

J. Mater. Chem. 2017,

17, 2283–2300.

[Google Scholar]

62.

Nazare S, Kandola BK, Horrocks AR. Flameretardant unsaturated polyester resin incorporating nano clays.

Polym. Advant. Technol. 2016,

17, 294–303.

[Google Scholar]

63.

Nguyen T, Patel R. Tailoring Thermal Conductivity in Waste Polyethylene-Based Composites.

Polym. Compos. 2017,

38, 810–818.

[Google Scholar]

64.

Saba N, Mohammad F, Pervaiz M, Jawaid M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites.

Polymers 2015,

7, 1–26.

[Google Scholar]

65.

Huang X, Netravali AN, Yan L. Sustainable Green Composites: Value Addition to Agricultural Residues and their Applications.

Sustain. Mater. Technol. 2016,

9, 1–17.

[Google Scholar]

66.

Zhang L, Wang Y, Li J, Chen S, Liu X, Zhao Q, et al. Recent Advances in Fire Retardancy of Polymeric Materials.

Prog. Polym. Sci. 2019,

92, 33–96.

[Google Scholar]

67.

Hu, Y, Zhou, Z, Li, S, Yang, D, Zhang, S, Hou, Y. Flame Retarded Rigid Polyurethane Foams Composites Modified by Aluminum Diethylphosphinate and Expanded Graphite.

Front. Mater. 2021,

7, 629284.

[Google Scholar]

68.

Levchik SV, Weil ED. Flame Retardancy of Polymer Layered Silicate Nanocomposites.

Polymer 2018,

45, 4227–4244.

[Google Scholar]

69.

Wang DY, Yuan B, Chen L, Cao X. Flame-Retardant and Smoke-Suppressant Polyethylene Terephthalate Nanocomposites Based on a Reactive Liquid Rubber.

J. Appl. Polym. Sci. 2017,

134, 44530.

[Google Scholar]

70.

Morgan AB. Fire-Retardant Polymeric Materials; Wiley: Hoboken, NJ, USA, 2015.

71.

Green A, Smith B, Johnson C, Lee D, Patel E, Kumar F, et al. Biodegradable Polymers for Sustainable Composite Materials: A Comprehensive Review.

Environ. Sci. Technol. 2021,

47, 4583–4596.

[Google Scholar]

72.

Wang X, Hu W, Hu Y. Polydopamine-Bridged Synthesis of Ternary h-BN@PDA@TiO2 as Nanoenhancers for Thermal Conductivity and Flame Retardant of Polyvinyl Alcohol.

Front. Chem. 2020,

8, 587474. doi:10.3389/fchem. 2020.587474

[Google Scholar]

73.

Bourbigot S, Duquesne S. Fire-retardant Polymers: Recent Developments and Opportunities.

J. Mater. Sci. 2018,

53, 9967–9986.

[Google Scholar]

74.

Zhang X, Li Y, Wang L, Chen J, Liu H, Zhao Q. Enhanced Fire Resistance of Polymer Composites with Nano-Additives: A Review.

Nanomaterials 2021,

11, 1587.

[Google Scholar]

75.

Li H, Wang Y, Zhang J, Chen S, Liu X, Zhao Q. Flame Retardant Polyethylene Composites with Wastepaper Fibers: A Novel Approach for Enhancing Fire Resistance.

Polym. Degrad. Stab. 2020,

173, 109078.

[Google Scholar]

76.

Curry B. Fire-Retardant Polyester Resin Formulations; AOC Technical Paper, SAGE JOURNALS: AOC in Collierville, Tennessee. 2013; pp. 1–3. Available online: https://journals.sagepub.com/doi/abs/10.1177/0892705718799814 (accessed on 22 November 2024).

77.

Cristiane M, Aline D, Fernando W, Sandro C. Mechanical and Flame-Retardant Properties of Epoxy/Mg–Al LDH Composites.

Compos. Part A 2018,

42, 196–202.

[Google Scholar]

78.

Chen JX, Jiao C. Synergistic Effects of Hydroxy Silicone Oil on Intumescent Flame Retardant Polypropylene System.

Fire Saf. J. 2019,

44, 10–40.

[Google Scholar]

79.

Harshvardhan S, Arun R, Alok K. Development and Characterization of Particulate Filled Glass Fiber Reinforced Hybrid Composites.

Int. J. Mech. Ind. Eng. 2012,

2, 2231–6477.

[Google Scholar]

80.

Akash, Girisha KG, Venkatesha Gupta NS, Sreenivas Rao KV. A Study on Flammability and Moisture Absorption behavior of Sisal/coir Fiber Reinforced Hybrid Composites.

IOP Conf. Series Mater. Sci. Eng. 2017,

191, 201–210.

[Google Scholar]

81.

Kandare E, Chukwudolue C, Kandola BK. The use of Fire-retardant Intumescent Mats for Fire and Heat Protection of Glass Fibre-reinforced Polyester Composites: Thermal barrier properties.

Fire Mater. Int. J. 2010,

34, 21–38.

[Google Scholar]