Found 3 results

Article

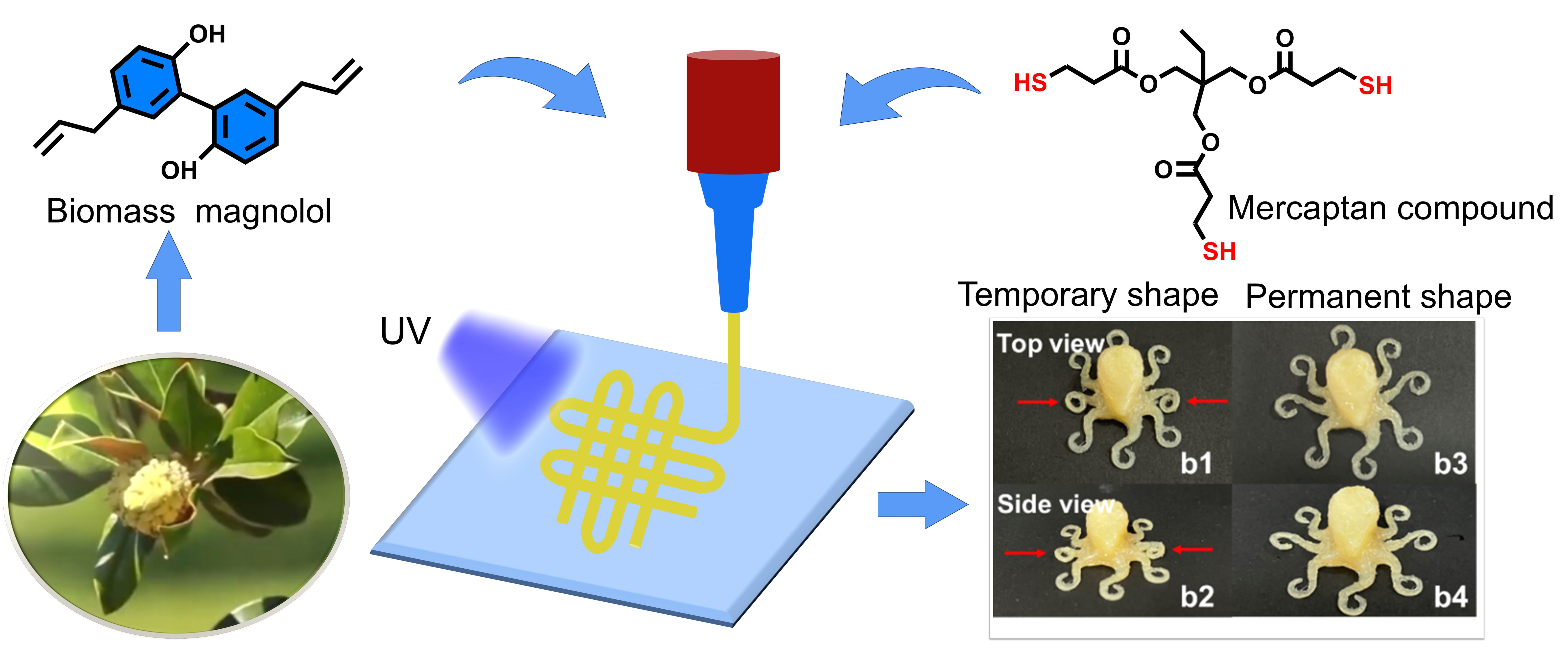

18 September 2024Direct-Ink-Writing Printing of Shape Memory Cross-Linked Networks from Biomass-Derived Small Molecules

The rapid development of 3D printing, also known as additive manufacturing, has opened up new opportunities for applying shape memory polymers (SMPs) in various fields. The use of abundant, inexpensive, and easily accessible biomass materials as printing raw materials not only facilitates the creation of more intricate SMPs but also aligns with the principles of low-carbon, green, and sustainable development. Here, we successfully printed a shape memory cross-linked network (NW-MO-TTMP) in a single step by direct-ink-writing printing and an in-situ thiol-ene click reaction with magnolol and trimethylolpropane tris(3-mercaptopropionate) as raw materials. The resulting NW-MO-TTMP network exhibited high mechanical properties and a tensile strength (σ) of up to 2.7 MPa when the thiol-ene ratio was 1.0:1, and the photo-initiator content was 1.5%. To improve printability, ethyl cellulose (EC) derived from biomass was incorporated to enhance the viscosity of the printing precursor fluid, resulting in a significant increase in the σ of the NW-MO-TTMP/EC network, reaching 20.6 MPa. Moreover, the successful printing of intricate models, such as the ‘whale’ and ‘octopus,’ demonstrated excellent shape memory effects. This approach highlights the potential of combining biomass-derived materials with advanced 3D printing techniques to develop sustainable and high-performance SMPs.

Review

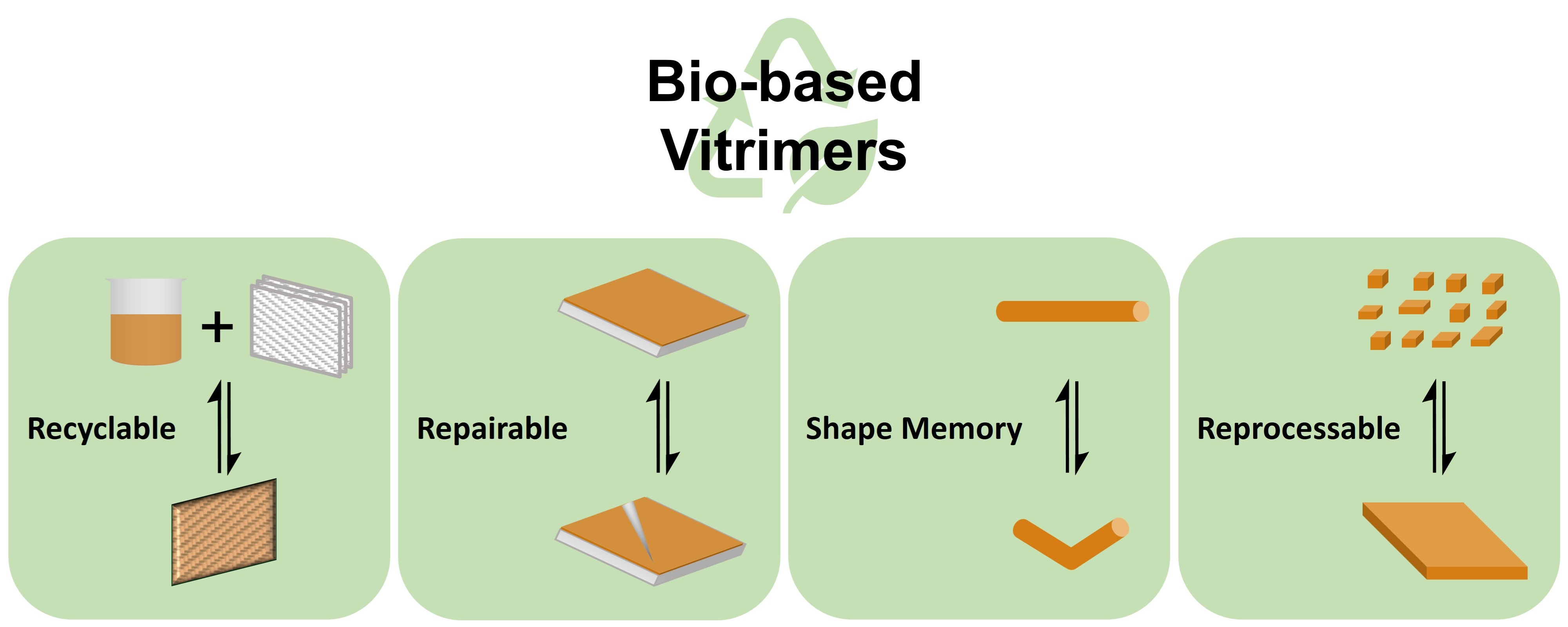

14 June 2024Biobased Vitrimers: A Sustainable Future

Vitrimers are crosslinked polymers containing dynamic covalent linkages. Because of their crosslinked structure, they are stable as thermosets at their service temperatures. At high enough temperatures, dynamic exchange reactions occur and rearrange the polymer network, thus vitrimers become malleable and reprocessable like thermoplastics. The dynamic covalent bonds can also undergo dissociative cleavage reactions under specific conditions, so vitrimers are inherently degradable. To achieve a sustainable future, various biomass resources have been used as raw materials in vitrimer preparation. This review summarizes recent developments in biobased vitrimers and highlights their preparation methods. The limitations of current biobased vitrimers are also discussed.

Review

24 July 2023Creating Shape Memory Polymers from Biobased Resources

Developing polymer materials from biomass is a promising pathway to address serious environmental and resource issues. To date, a series of biobased general polymer materials have been successfully industrialized. However, exploring highly valuable functional polymers and intelligent polymer materials from biomass, such as shape memory polymers (SMPs) and self-healing materials, is still a great challenge. The present review intends to bridge a sustainable pathway for the creation of SMPs from biobased resources. Thus, we first recall some backgrounds of the design principle of SMPs and highlight the biobased monomers or building blocks for SMPs, and then we focus on the main varieties of biobased SMPs to clarify their fabricating approaches, functionalizing strategies, new manufacturing methods and the application potential.