Found 1 results

Review

25 February 2025Innovations in IN939: From Cast Alloy to Additive Manufacturing

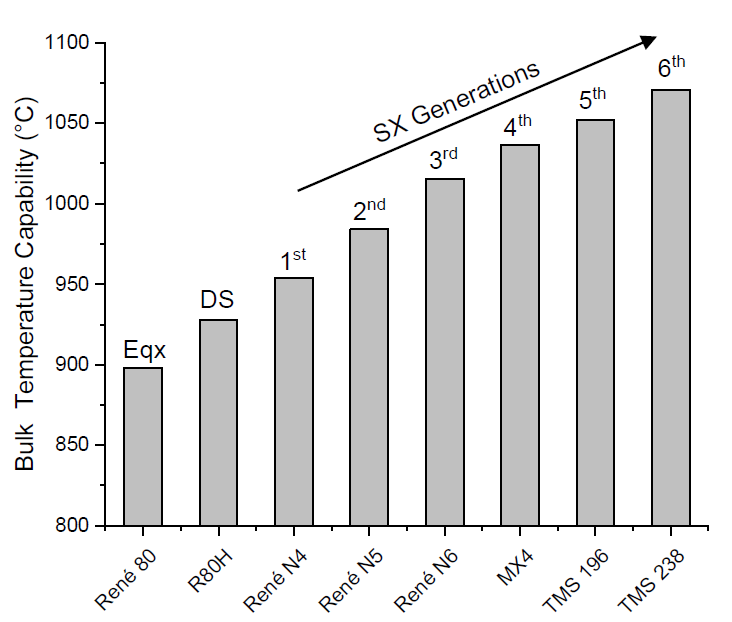

Nickel-based superalloys are the most reliable material choice for the hot sections of turbines. These superalloys are mainly employed in aircraft engines, particularly in the combustor and turbine sections. In this scenario, the growing need for materials that can endure high temperatures while retaining their strength has driven the development of IN939. Although IN939 holds these significant important properties and applications, it has received less attention in recent literature than other superalloys. This review aims to comprehensively analyze the main research on IN939 over the past 50 years. From 1970 to 1980, research primarily focused on the development of IN939 through casting methods. Between 1980 and 1990, the emphasis shifted to studying its oxidation resistance and microstructural stability during service. The period from 1990 to 2000 focused on repairing components after long service time at high temperatures. In recent decades, advances in additive manufacturing techniques have led to growing interest in developing IN939 using methods like laser powder bed fusion (LPBF). Research in the area has demonstrated that the LPBF technique offers a promising approach to manufacturing high-performance IN939 components.