Found 2 results

Article

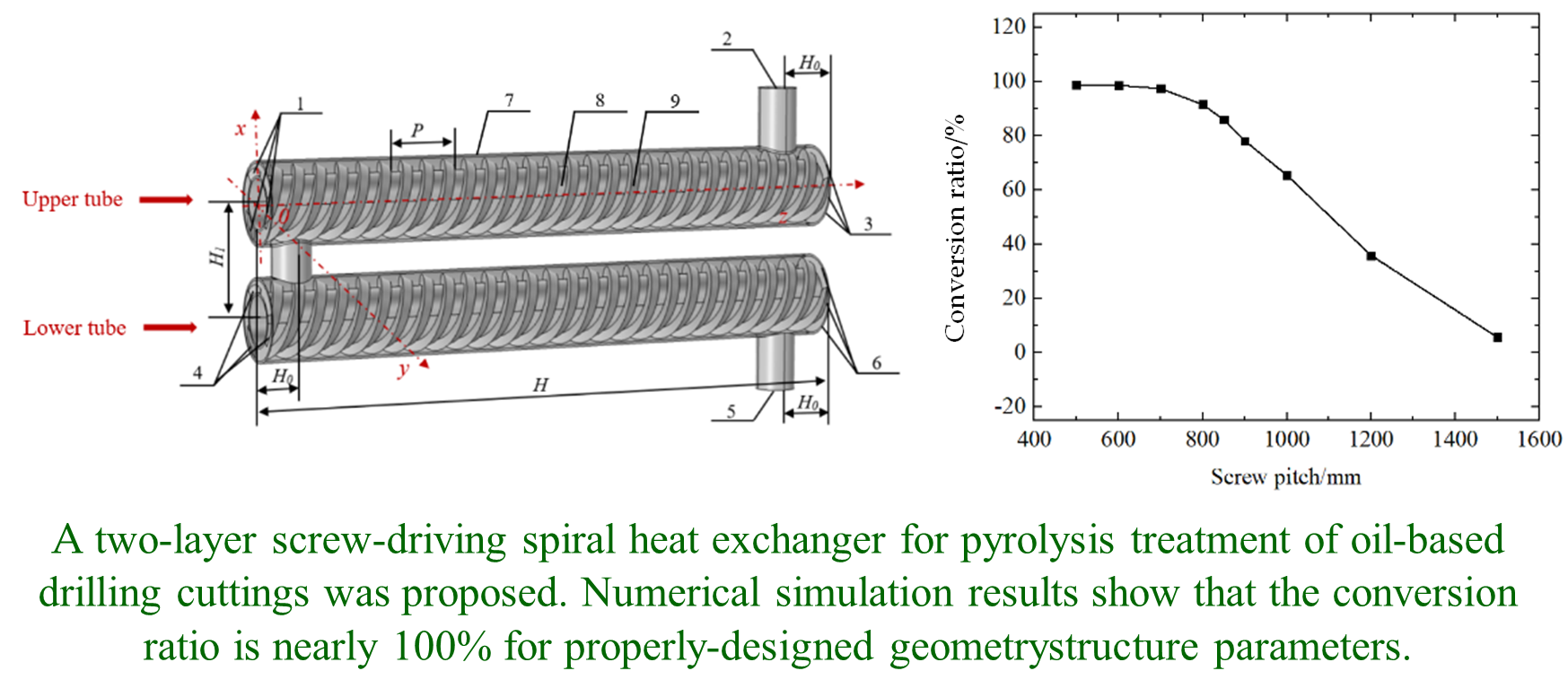

23 May 2024Numerical Study on Pyrolysis Characteristics of Oil-Based Drilling Cuttings in a Two-Layer Screw-Driving Spiral Heat Exchanger

Oil-based drilling cuttings is a pollutive nearly-solid waste produced in oil exploitation that has to be treated for meeting clean production requirement of oil and gas exploration. A two-layer screw-driving spiral heat exchanger was thus proposed for this purpose. To investigate its effectiveness and performance, a 10-component n-decane one-step product proportional distribution chemical model was used to describe oil-based drilling cuttings pyrolysis process, and numerical simulations were carried out of forced convection inside the heat exchanger with a full consideration of pyrolysis and evaporation effects. The influences of rotation speed, screw pitch and cross-sectional shape of spiral tube on pyrolysis, flow, and heat mass transfer characteristics were studied. The results show that the heat absorbed needed for evaporation is much less than that for pyrolysis, and the heat transfer coefficient with consideration of evaporation and pyrolysis is almost two times greater than that without. The pyrolysis rate increases first, and then decreases once the temperature is higher than 838 K due to the coupled effects of temperature and reactant concentration change. The velocity, heat transfer coefficient and conversion ratio of oil-based drilling cuttings all increase with rotation speed, but the conversion ratio increase becomes slower and slower once the rotation speed exceeds 0.2 rad·s−1. The average vorticity and flow resistance of oil-based drilling cuttings both decrease with screw pitch monotonously, while heat transfer coefficient increases first and then decreases because of the opposite effects of centrifugal force and thermal entrance length. Reducing screw pitch can increase conversion ratio, but once screw pitch is smaller than 800 mm, the conversion ratio approaches to a constant. Cross-sectional shape of spiral tube also affects pyrolysis performance, and circular cross-sectional spiral tube seems to be the best.

Article

15 August 2023Thermal and Economic Evaluations of a Drain Water Heat Recovery Device under Transient Conditions

This study explores the transient characteristics of a drain water heat recovery (DWHR) device employed for heat recovery from warm grey water in buildings. Experimental measurements were conducted to investigate the response time of the DWHR device under various flow conditions. The thermal performance of the system was assessed using both transient and steady-state effectiveness analyses. The findings reveal that the response time is influenced by the water volume within the system, with an increase observed, and by the water flow rate, which leads to a decrease in response time. Additionally, a decrease in effectiveness is noted when hot water is used in short and frequent intervals. Furthermore, an economic analysis demonstrates that considering the transient behavior of the device results in a significant overall decrease of 37% in annual savings. Specifically, the usage of sinks exhibits a reduction in annual savings by 56%, while showers show a decrease of 13% in annual savings.