Found 3 results

Review

06 December 2024Recent Progress of High Safety Separator for Lithium-Ion Battery

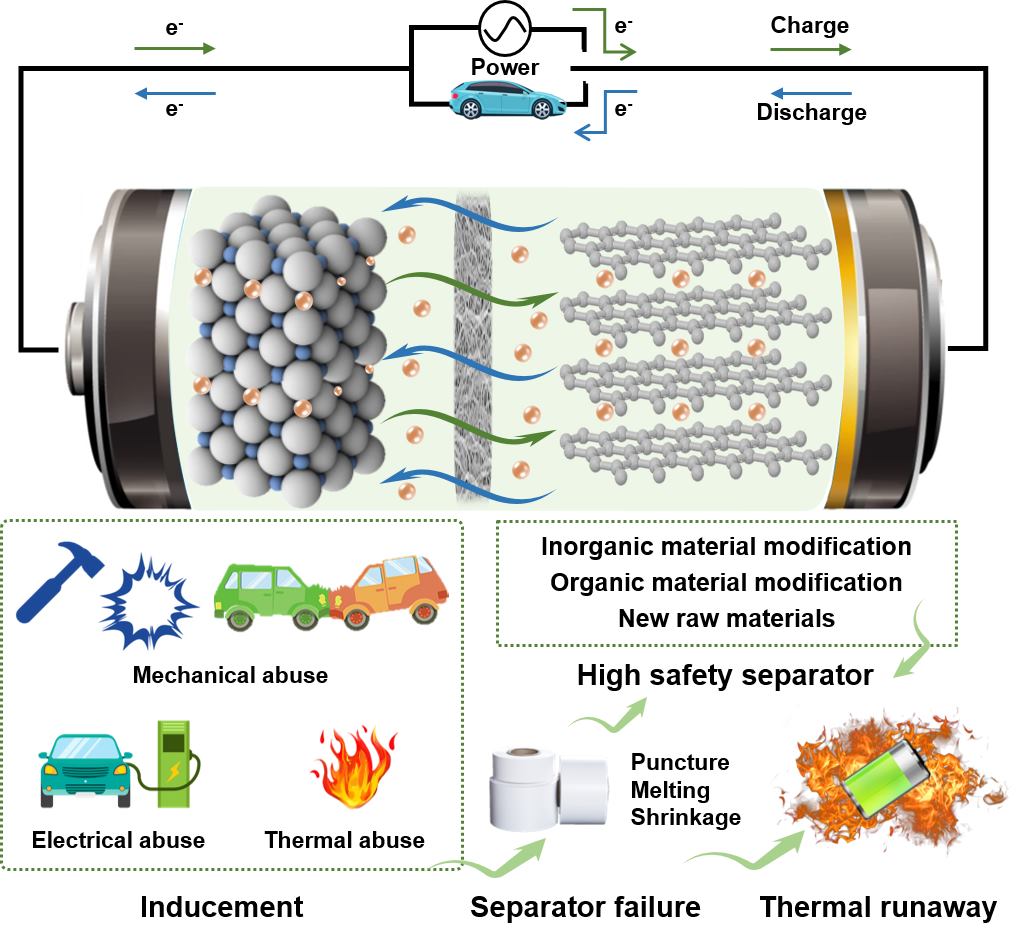

With the rapid increase in quantity and expanded application range of lithium-ion batteries, their safety problems are becoming much more prominent, and it is urgent to take corresponding safety measures to improve battery safety. Generally, the improved safety of lithium-ion battery materials will reduce the risk of thermal runaway explosion. The separator is a key component of lithium-ion batteries. It plays a crucial role in battery safety, serving as one of the most effective measures against internal short circuits.Separator failure is a direct cause of the thermal runaway and can be specifically divided into three categories: puncture, melting, and thermal shrinkage. The requirements for an ideal lithium-ion battery separator have a synergistic effect on the electrochemical performance, safety, and scalability of lithium-ion batteries. Focus on the separator, this review summaries the mechanism of separator in thermal runaway process, and reports the recent progress of high safety separator from the perspective of material preparation.

Article

02 September 2024Lithium-Rich Spinel Cathode with Higher Energy Density for Sustainable Li-Ion Batteries Operating in Extended Potential Range

Lithium batteries pave way for rapidly reducing greenhouse gas emissions. Still there are concerns associated with battery sustainability, such as the supply of key battery materials like cobalt, nickel and carbon emissions related to their manufacture. While LiMn2O4 spinel is a common cathode material for Li-ion batteries that remove Co and Ni, studies on over-stoichiometric variants and their behavior across a broad potential range may be limited. Research in this area could provide valuable insights into the performance, stability and electrochemical characteristics of such cathodes, offering potential benefits for the development and optimization of Li-ion battery technologies. This study investigates the electrochemical behavior of Li-rich Li1+yMn2−yO4−δ (LMO, y ≈ 0.03, δ ≈ 0.01) spinel as a cathode in Li-ion batteries, focusing on the phenomenon of extra capacity under the extended operating voltage 1.5–4.8 V vs. Li+/Li. The nanostructured LMO sample synthesized by sol-gel method and calcined at 900 °C is characterized by X-ray diffraction, scanning and transmission electron microscopy and surface area measurements. The Li-rich spinel electrode delivers a specific discharge capacity of 172 mAh g−1 at 1st cycle. It retains 123 mAh g−1 at the 100th cycle (71.5% capacity retention) at current density of 100 mA g−1 current density (i.e., ~0.7 C rate). An excellent stability is obtained in the 1.5–4.8 V potential window, with a discharge capacity of 77 mAh g−1 after 500 cycles at the same current density, owing to the reduction of the Jahn-Teller effect by Li doping. These results contrast with the specific capacity of 85 mAh g−1 (1st cycle) and the capacity retention of 54.3% after 100 cycles, obtained when the cell operates in the narrow potential range of 3.0–4.5 V.

Review

15 March 2023Ultra-Thin Solid Electrolyte in Lithium-Ion Batteries

Safety concern of lithium-ion battery, attributed to using volatile and flammable liquid electrolytes, could be addressed by using solid electrolytes. Solid electrolytes including inorganic solid electrolytes, polymer solid electrolytes and organic/inorganic composite electrolytes have the common drawbacks in low ion-conductivity. Much efforts have been devoted to increase the specific ion conductivity, especially for inorganic solid electrolyte whose intrinsic conductivity is close to liquid electrolyte. However, most solid-state electrolyte membranes in lithium-ion batteries are thick, resulting in long ion-conduction pathway, low energy density and high cost. In this review, the advantages and disadvantages of different kinds of solid electrolytes were analyzed, and the promising strategies of ultra-thin solid electrolyte preparation were summarized and prospected. Applied organic-inorganic composite, continuous phase enhancement and in situ integration have been devoted to reducing thickness of electrolyte membrane and improving battery performance. On the basis of the technical requirement of lithium-ion batteries, this review aims to provide a guidance in terms of rational design and synthesis of ultra-thin solid electrolytes for the further research that addresses the safety issues and improves cycling performance of batteries.